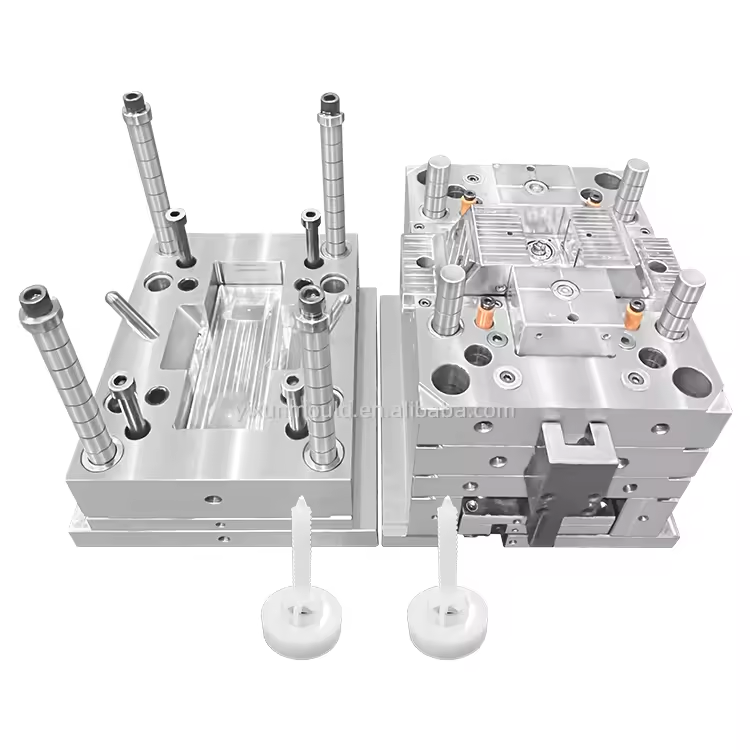

Moules d'injection en aluminium

Rapid Tooling Solutions

Leading manufacturer specializing in high-performance aluminum injection molds for rapid prototyping and low volume production. Our advanced tooling solutions deliver superior thermal conductivity, faster cycle times, and exceptional cost-effectiveness for demanding applications.

Why Choose Aluminum Injection Molds?

Superior performance advantages for rapid manufacturing and prototyping

Cost-Effective

30-50% lower tooling costs compared to steel molds, ideal for budget-conscious projects and small production runs.

Rapid Manufacturing

Faster machining speeds and shorter lead times enable quick prototyping and accelerated time-to-market.

Superior Thermal Conductivity

5x better heat dissipation than steel reduces cycle times by up to 50% and improves part quality.

Easy Modification

Aluminum’s malleability allows for quick design changes and modifications during development phases.

Conception légère

Reduced mold weight improves handling safety and reduces machine wear during production.

Respectueux de l'environnement

100% recyclable aluminum material supports sustainable manufacturing practices.

Premium Aluminum Alloys

High-performance materials optimized for injection molding applications

6061-T6 Aluminum

- Excellente résistance à la corrosion

- Good weldability and formability

- Ideal for low-volume production

- Cost-effective solution

7075-T6 Aluminum

- Rapport résistance/poids élevé

- Excellent fatigue resistance

- Aerospace-grade quality

- Complex geometry capability

Aluminum vs Steel Molds Comparison

Understanding the advantages for your specific application

| Comparison Factor | Aluminum Molds | Steel Molds |

|---|---|---|

| Coût initial | 30-50% Lower | Plus élevé |

| Lead Time | 15 Days | 6-12 Weeks |

| Conductivité thermique | 5x Better | Standard |

| Cycle Time | 50% Faster | Longer |

| Modification | Easy & Quick | Difficile |

| Production Volume | 100-10,000 Parts | 10,000+ Parts |

Diverse Industry Applications

Trusted solutions across multiple sectors

Automobile

Interior components, housings, connectors, and functional prototypes

Medical

Surgical instruments, device housings, and diagnostic equipment

Électronique

Enclosures, heat sinks, connectors, and consumer device components

Produits grand public

Appliances, sporting goods, toys, and household items

Advanced Manufacturing Capabilities

Comprehensive tooling solutions from concept to production

Precision Manufacturing Process

CNC Machining Excellence

- High-speed 5-axis CNC machining

- Precision tolerances ±0.005″

- Complex cavity geometries

- Automated tool changing systems

EDM & Wire EDM

- Intricate detail machining

- Sharp corner radii capability

- Thin wall sections

- Superior surface finish

Quality Assurance

- CMM dimensional inspection

- Surface roughness testing

- Mold trial optimization

- ISO 9001:2015 certified

Spécifications techniques

Mold Capabilities

Compatible Materials

À propos de RAPIDPRECISE

Leading Chinese manufacturer specializing in precision aluminum injection molds and rapid tooling solutions. With over 15 years of experience, we serve global clients across diverse industries with innovative, cost-effective manufacturing solutions.

Comprehensive Service Portfolio

End-to-end solutions from design to production

Conception en ingénierie

- DFM Analysis

- 3D Modeling

- Analyse de flux de moule

- Tool Design Optimization

Rapid Prototyping

- Moules à rotation rapide

- Sample Production

- Design Iterations

- Function Testing

Production Services

- Low Volume Manufacturing

- Bridge Tooling

- Assembly Services

- Packaging Solutions

Ready to Accelerate Your Production?

Découvrez les avantages des moules en aluminium pour votre prochain projet. Obtenez une consultation d'expert et des devis compétitifs de la part de notre équipe d'ingénierie.

Demandez un devis maintenant

Produits associés affichés

Voici le seul résultat